LP 3000

Hydraulic Rubber Laboratory Presses

Montech’s state-of-the-art hydraulic laboratory presses ensure the most uniform test specimens for rubber and silicone applications.

Available Capacities: 20 | 40 | 60 | 100 | 150 Tons

With commitment to ASTM D3182 & ISO 2393, MonTech hydraulic presses feature the newest technology for compression molding elastomer test specimens. The advanced industrial design, unmatched temperature uniformity and platen parallelism, give laboratories the assurance that their users will produce the best test samples for the lifetime of the machine.

Whether in Quality Control or R&D, our customizable options allow for more flexibility in press capabilities, tailor-made to suit any unique application.

Laboratory Press Technology

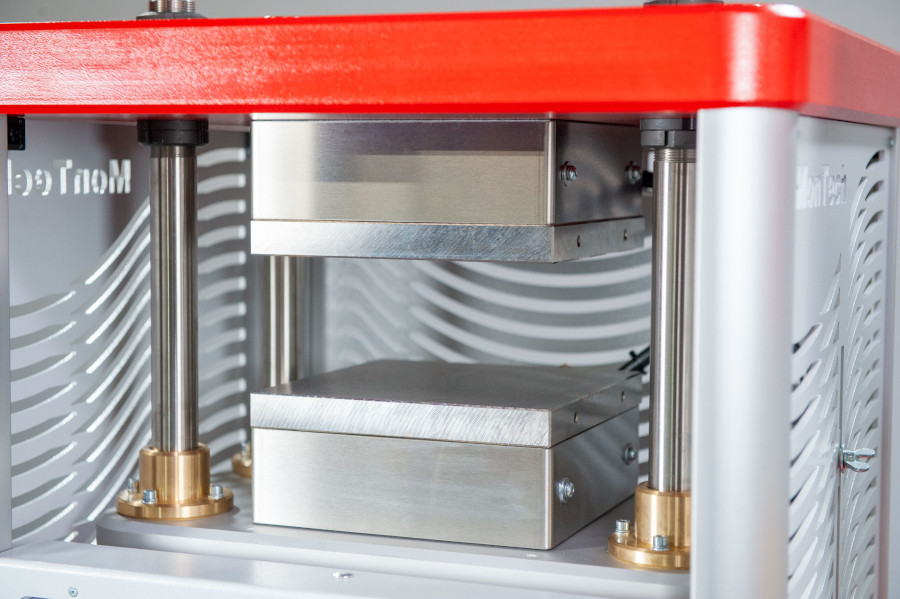

- Fully enclosed frame design – controls, hydraulics, hoses, piping.

- Centralized PLC control

- Wear resistant stainless steel platens

- Linear encoder for piston positioning

- Energy efficient technology

- Precision proportional control

- Four post oversized precision guiding

- Temperature stabilization monitoring

- Safety forward design

20 Ton

40 Ton

60 Ton

100 Ton

150 Ton

Designed to the Standard

Did you know that 95% of presses in circulation cannot meet short or long-term requirements for optimal sample preparation? Aligned with ASTM D3182 & ISO 2393 MonTech presses outperform every competitor by meeting the platen parallelism, temperature uniformity, and PSI requirements.

- Temperature Accuracy: ± 0.5°C

- Platen Parallelism: Better than 0.1 mm/m

- Platen Surface PSI: 500 PSI

The Energy Efficient Lab Press

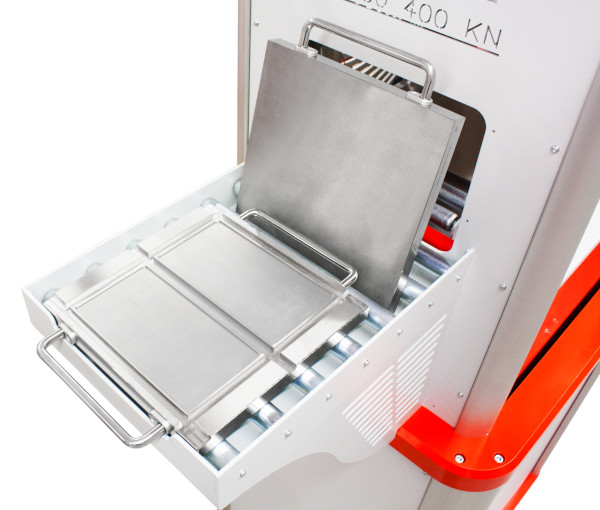

MonTech laboratory presses designs prioritize energy efficiency. Each platen is equipped with state-of-the art insulation and stainless-steel covers to mitigate temperature loss. All presses are installed with an IE4 high-efficiency hydraulic pump motor requiring less oil, offering more control, and no longer demand an inefficient heat exchanger.

Laboratory Press Customization

The applications in the elastomer’s world are endless. That’s why we offer more options for customization, ensuring your press meets specifications for ergonomics, safety, workflow efficiency, and production.

- Single, Double, or Triple Daylight

- High-Temperature Versions

- Low-Force Pressure Operation

- Customized cycle programming

- Open-Loop or Closed-Loop cooling systems

- MonPress Data Acquisition Software

- Ergonomic Press Tables

- Additional PT100 Channels

- Over a dozen additional safety options

- And much more…

Technical Specifications

Lab Press Model | LP 3000 - | LP 3000 - | LP 3000 - | LP 3000 - | LP 3000 - |

Hydraulic Type | Tabletop | Floorstanding | Floorstanding | Floorstanding | Floorstanding |

Capacity Range | 12 - 200 kN | 50 - 400 kN | 40 - 600 kN | 60 - 1000 kN | 100kN - 1500kN |

Press Platen Size | 7.71 x 7.71 in | 11.65 x 11.65 in | 17.56 x 17.56 in | 19.53 in x 19.53 in | 23.46 x 23.46 in |

Pneumatics | 4.5 bar / 65 psi | 4.5 bar / 65 psi | 4.5 bar / 65 psi | 4.5 bar / 65 psi | 4.5 bar / 65 psi |

Electrical | 480 / 277 Volt, 60 Hz, | 480 / 277 Volt, 60 Hz, | 480 / 277 Volt, 60 Hz, | 480 / 277 Volt, 60 Hz, | 400 Volt, 50/60Hz ≈100 Amps, |

Daylight Options | Single | Single | Single | Single | Single |

Pressing Speed | 1.5 - 3 mm/s | 1.5 - 3 mm/s | 1.5 - 3 mm/s | 1.5 - 3 mm/s | ≈1.2 to 2 mm/s |

Cylinder Stroke | 3.94 in (100 mm) | 11.81 in (300 mm) | 7.87 in (200 mm) | 11.81 in (300 mm) | 11.81 in (300 mm) |

Opening Stroke Speed | 20mm/s | 20mm/s | 20mm/s | 20mm/s | ≈16mm/s |

Closing Stroke Speed | 30mm/s | 30mm/s | 30mm/s | 30mm/s | ≈20mm/s |

Platen Pressure | 5.21 N/mm2 | 4.57 N/mm2 | 3.02 N/mm2 | 5.03 N/mm2 | 4.22 N/mm2 |

Heating Type | Electrical | Electrical | Electrical | Electrical | Electrical |

Capacity Per Platen | 2.8 kW | 4.0 kW | 6.0 kW | 6.0 kW | 10.0 kW |

Max. Temperature | 250°C / 480°F | 250°C / 480°F | 250°C / 480°F | 250°C / 480°F | 250°C / 480°F |

Temperature Accuracy | ±0.5°C | ±0.5°C | ±0.5°C | ±0.5°C | ±0.5°C |

Dimensions (H x W x D) | 38.19 x 31.10 x 21.65 in | 66.73 x 31.50 x 23.23 in | 68.90 x 49.21 x 31.50 in | 76.77 x 57.09 x 31.50 in | 70.87 x 77.95 x 47.24 in (1800 x 1980 x 1200 mm) |

Weight | 992 lbs (450 kG) | 1764 lbs (800 kG) | 2425 lbs (1100 kG) | 3086 lbs (1400 kG) | 5512 lbs (2500 kG) |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified