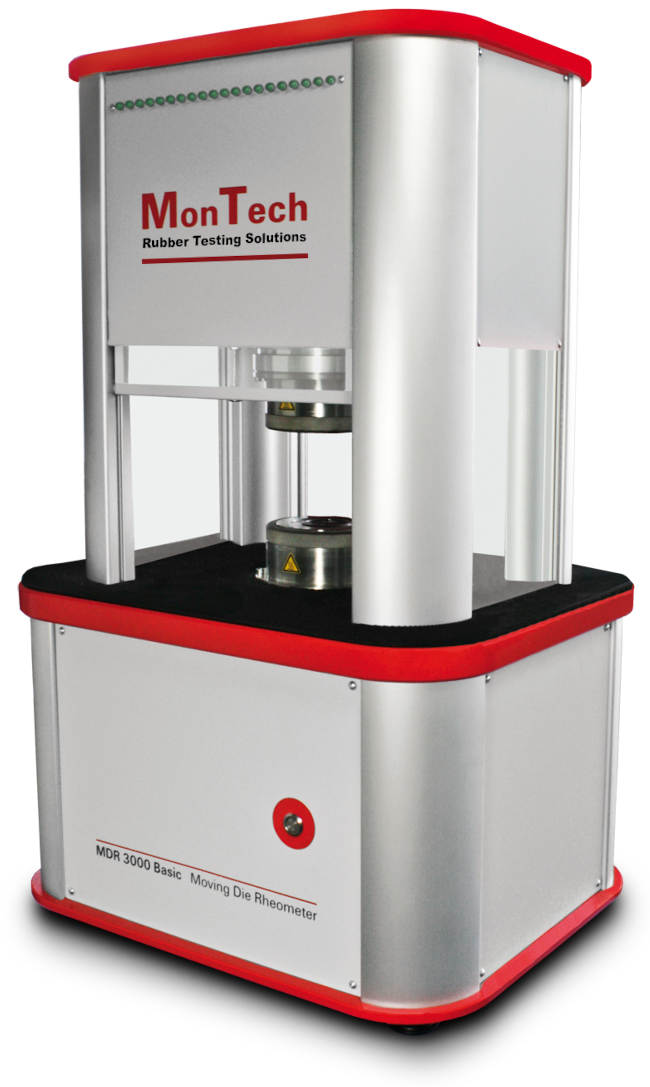

MDR 3000 Basic

Moving Die Rheometer

Entry-level Moving Die Rheometer for rubber cure analysis

MDR cure rate analysis is the most common and essential test for mixing batch release or incoming quality control. The MDR 3000 Basic, gives compounders and rubber product manufacturers peace of mind knowing their materials will vulcanize as intended. With a host of advanced options, a brushless DC motor with integrated drive control, intelligent transducer technology, and more – users can expect the best accuracy for quick quality control checks or simple R&D applications.

Simple Operation. Quick Results.

- Brushless DC Motor with integrated drive control system - ideal for static testing

- Aerospace grade aluminum and stainless-steel framing for tough production environments or laboratory settings

- Easy to use instrument control software with integrated self-diagnostics

- Fanless Design – no more air particulate related electronics failures

- Equipped with state-of-the-art programmable logic controller for the fastest data sampling rate

- Furnished with intelligent transducer technology for the highest measurement precision

- Hundreds of cure rate data points to choose from

- Host-system linkable for easy integration into any laboratory

Load. Test. Remove. Repeat.

Automation should make your life easier, not harder. Production laboratories with high testing throughput depend on reliable automation to match the number tests to accomplish. Engineered robotics, or linear film feeding, guide the sample with ease onto the die cavity where testing may commence. Once the test is finished, the outhaul conveyor effortlessly removes the sample from the die area, making way for the next test.

Automation Types:

- Tray Autoloader: 24, 48 or 100 samples per tray

- Linear Autoloader: 5 or 10 sample linear feeding

Industrial Electronics That Endure. Controls That Deliver.

The leaders in rubber product manufacturing demand the highest standard in industrial electronics. The MDR 3000 Basic’s PLC controls all functions in the instrument, from operation to data recording. Designed by one of the top three European producers of industrial PLCs, the MDR’s PLC is considered an industrial standard across high-tech industries and advanced automation applications. It’s fully digital with no analogue signal processing. If something goes wrong, its modular design enables quick replacements if necessary and is available for remote diagnostics.

Technical Specifications

Standards | ISO 6502 |

Test Chamber | Bi-conical, closed System |

Electrical | 110-120V, 8 Amps or 200-240 V, 5 Amps, 47-63 Hz Single Phase |

Pneumatics | min. 4.5 Bar / 60 psi |

Dimensions (H x W x D) | 36.6 in x 22.8 in x 19.7 in (93 cm x 58 cm x 50 cm) |

Drive System | Mechanical, brushless DC eccentric drive |

Sample Volume | approx. 4.5 cm3 |

Torque Range | 0.01 to 235 dNm | 0.01 to 208 in.lb |

Oscillation Frequency | 1.667 Hz (100 cpm) |

Oscillation Strain | +/- 0.1°, 0.2°, 0.5° (Standard), 1° or 3°, Mechanically adjustable (+/- 1.4%, 2.8%, 7% (Standard), 14% or 42%) |

Measured Data | Torque (dNm, lbf.in, kgf.cm), Temperature (°C, °F), Pressure (bar, kg per cm²), Time (min - min / min - sec / sec), Shear rate (1/s, rad/s), Cure rate (1/min, 1/sec) |

Calculated Data | S΄, S˝, S*, tan δ, phase angle, cure speed, ... |

Data Points | Over 3500 data points available for each test Including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90 |

Data Interface | Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (optional) |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified