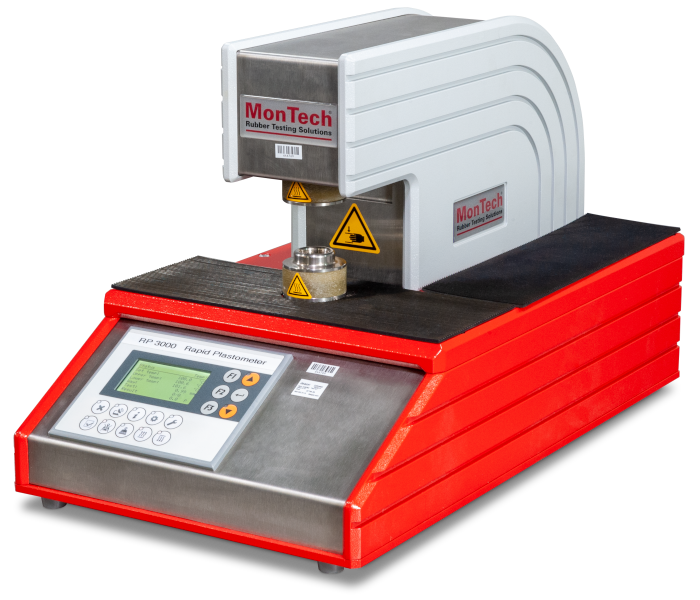

RP 3000

Rapid Natural Rubber Plastimeter

Rapid Plastimeter for accurate measurement of Natural Rubber Plasticity Retention Index (PRI) and stability.

The PRI is renowned for its reliability and standardization throughout the industry. Rapid Plastimeters that attain the PRI measurement, following ISO 2930, indicate how well the natural rubber (NR) performs with thermal-oxidative stability. It is a critical quality control metric and is commonly found amongst tire manufacturers, NR plantations, and other industrial consumers of NR. All Rapid Plastimeters are typically purchased with plasticity aging ovens (PO 3000) and specimen cutters (P-VS 3000 M).

RP 3000 Features

- Fully automatic and easy operation

- Heavy duty aluminum and stainless-steel frame

- Single / median operational modes

- Automated calibration

- Built-in diagnostics

- Variable platen temperatures 25°C - 200°C

- Flexible conditioning steps and load times

- Digital temperature display

- MonPlast software for calculation and display of plasticity curve

Double working sample cutter

PO 3000 Ageing Oven for Plasticity Testing

Technical Specifications

Standards | BS 903:Pt A59: section A59.1 |

Platen Sizes | 10 mm, 7.3 and 14 mm diameter |

Platen Temperature | 25°C - 200°C |

Test Time | Default: 15 secs conditioning, 15 secs load |

Compressive Force | 100 N |

Data Interface | RS 232 |

Weight | approx. 35 kg net |

Electrical | 90-250 V, 6 Amps, 47-63 Hz, Single phase |

Optional Items | - MonPlast computer software |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified