Moving Die Rheometers

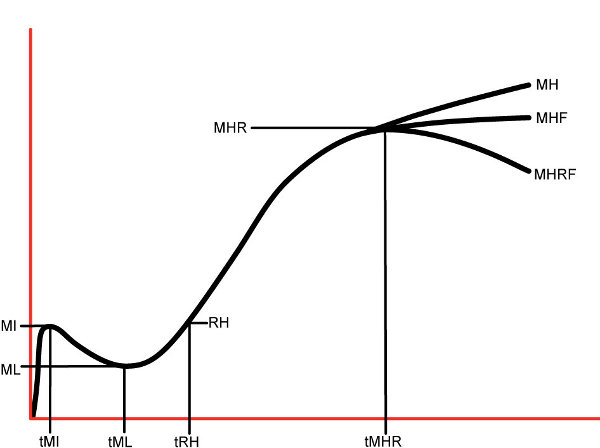

The rubber Moving Die Rheometer (MDR) and Rubber Process Analyzer (RPA) are the industrial standard to discover the optimal cure time of rubber and characterization of all compounds before, during, and after vulcanization. While MDRs give insights into the rubber curing data, the RPA enables all users a window into dynamic mechanical properties, rubber processing characteristics and much more.

Static Testing

Static curemeters are designed to test mixed rubber compounds under isothermal test conditions with fixed strain and frequency.

MDR 3000 Basic

Benchtop Moving Die Rheometer

- Drive System

Mechanical

Brushless DC eccentric drive - Oscillation Frequency

1.667 Hz - Oscillation Strain

± 0.1°, 0.2°, 0.5°, 1°, 3°, or 7.17°

mechanically adjustable - Measured Data

Torque, temperature, frequency

Optional: Normal force - Calculated Data

S΄, S˝, S*, tan δ

- Sample Automation

Linear: 5 or 10 samples

Tray: 24 or 48 samples - Pneumatic Cooling System

Optional

MDR 3000

Standard Moving Die Rheometer

- Drive System

Direct

Wearless servo drive system - Oscillation Frequency

1.667 Hz - Oscillation Strain

± 0.01° to 5°

programmable via software - Measured Data

Torque, temperature, frequency, strain

Optional: Normal force - Calculated Data

S΄, S˝, S*, tan δ

- Sample Automation

Linear: 5 or 10 samples

Tray: 24, 48, or 100 samples - Pneumatic Cooling System

Optional

Dynamic Testing

Dynamic curemeters are Dynamic Mechanical Rheological Testers (DMRT) designed to measure material properties of raw elastomers or mixed rubber before, during and after cure in a single test.

MDR 3000 Professional

Performance Moving Die Rheometer

- Drive System

Direct

Wearless servo drive system with ceramic bearings - Oscillation Frequency

0.001 Hz to 100 Hz

(0.001 Hz to 50 Hz optional) - Oscillation Strain

± 0.01° to 20°

(± 0.01° to 90° optional) - Measured Data

Torque, temperature, frequency, strain

Optional: Normal force - Calculated Data

S΄, S˝, S*, G΄, G˝, G*, tan δ, η΄, η˝ and η*

- Sample Automation

Linear: 5 or 10 samples

Tray: 24, 48, or 100 samples - Pneumatic Cooling System

Optional - MCool 10

D-RPA 3000

Rubber Process Analyzer

- Drive System

Advanced

Wearless servo drive system with ceramic bearings - Oscillation Frequency

0.001 Hz to 100 Hz - Oscillation Strain

± 0.001° to 360° - Measured Data

Torque, temperature, frequency, strain

Optional: Normal force, die gap, die pressure - Calculated Data

S΄, S˝, S*, G΄, G˝, G*, tan δ, η΄, η˝ and η*

- Sample Automation

Linear: 5 or 10 samples

Tray: 24, 48, or 100 samples - Pneumatic Cooling System

Standard - MCool 10

- MCool -40

MonTech Moving Die Rheometer systems are the foundation for reliable, accurate and repeatable testing results in the rubber industry – offering a unique design with an extremely rigid test frame and superior temperature control. All MonTech rotorless rubber curemeters are equipped with a closed, sealed, and biconical die system according to all relevant ISO, ASTM and DIN standards.

Every rubber testing machine is supplied with the flexible and easy to operate MonControl Software for managing test specifications, acquiring rubber cure graph data, or advanced dynamic properties.

All MDRs or RPAs may be configured to meet customer specific needs including a modular platform of automation solutions, cooling options, advanced data collection and sample preparation systems.

Heavy-Duty Machine Frame and Housing

Constructed from aerospace grade aluminum and stainless steel, MonTech rheometers have the most must rugged machine structure on the market.

The design includes the following specifications for superb die symmetry and alignment:

- Baseplate thickness: 80 mm

- Stainless Steel Pullrods: 50 mm diameter

- Crosshead: 80mm

- Side panel thickness: 20 mm

The stiffness of each frame directly improves repeatability and result correlation by reducing signal-to-noise ratio and improving damping.

Each frame is used as a heat sink and completely sealed preventing harmful contaminates (i.e. carbon black dust) from entering the housing.

The massive metal machine frame doubles as a heat sink, removing the need for fans, allowing the unit to be sealed against harmful contaminates (i.e. carbon black dust).

As only high-quality materials are used in their construction, MonTech instruments are a secure investment.

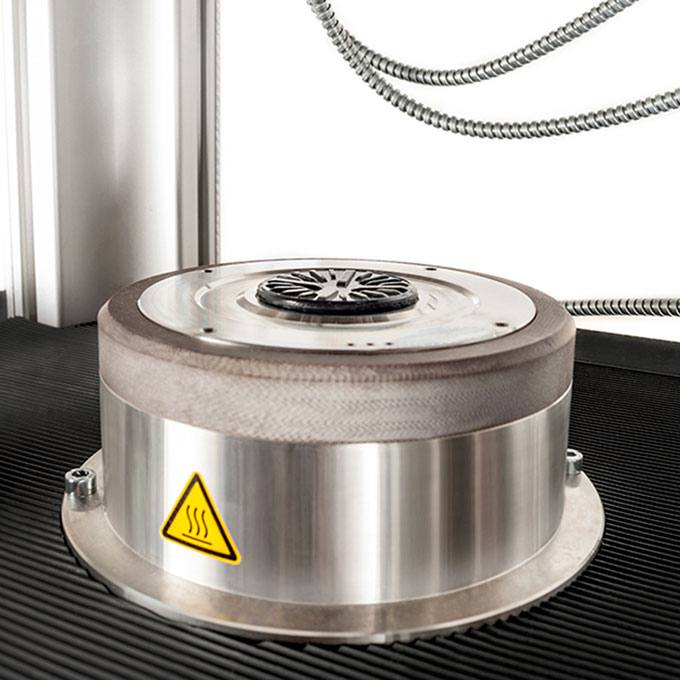

Test Die Assembly

MonTech Moving Die Rheometers are equipped with a biconical die assembly featuring:

- Direct heating

- Accurate sample temperature measurement

- Superior temperature control with unbeaten accuracy

- Highest heating and cooling rates

- Fastest response times

The die and crosshead are designed for unmatched uniformity and parallelism to improve accuracy.

All test dies are precision ground and polished from lot-traceable, hardened stainless steel for extreme stiffness and durability against the most abrasive compounds.

Closing System

Equipped with the most reliable die closing system, all MonTech rheometers can be optionally outfitted with cavity pressure measurement and die gap control. These modules, combined with the heavy load frame, guarantee the highest possible level of accuracy, reproducibility and reliability for any elastomeric application.

Integrated Calibration and Diagnostics

MonTech instruments feature internal diagnostic and condition monitoring routines for every critical process, enabling the instrument to detect, report and even solve potential problems before they occur.

MonControl software makes running diagnostics or verifying calibrations easy for users through guided program sequences.

Readings produced through calibration sequences are captured by the internal software of each machine, eliminating manual entry of verification data. Once the verification process is complete, a detailed PDF Report with all critical data is generated, ensuring traceability and conformance to industry quality standards.

Precision Torque Measurement and Transducer System

MonTech’s intelligent transducer and loadcell technology guarantees the highest accuracy and precision across the widest measurement ranges and highest dynamic loads. Proprietary transducers possess variable amplification, stiffness control and temperature compensation, promising precision to the smallest Milli-Newton.

All transducers are manufactured in-house for guaranteed clean-room quality production and testing.

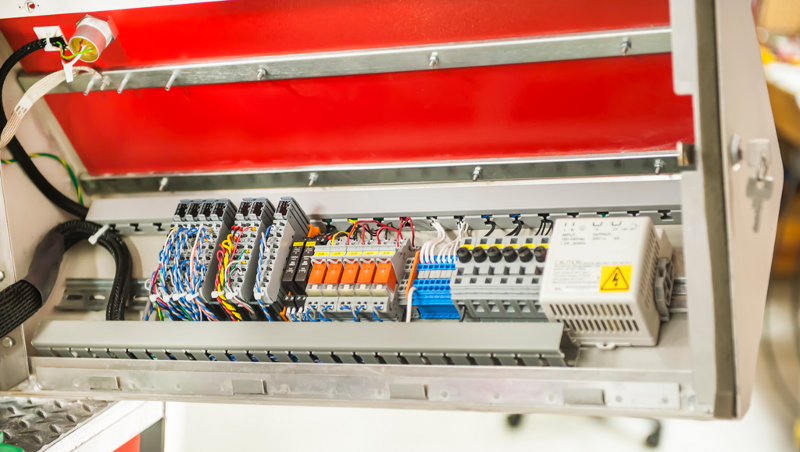

Integrated Data Processing

Programmable Logic Controllers form the foundation of every MonTech testing instrument, providing customers with proven technology for the highest system reliability and data rates.

The advanced 24-bit electronics with 10kHz high speed data sampling rate analyzes the complex data streams in real time. Superior data oversampling supplies the user with true measured results.

This technology reveals compound data including higher harmonics, nonlinearities and behavior at extreme processing conditions.

Powerful Drive Technology

Static Drives

MonTech static rheometers feature a geared, brushless DC motor with integrated drive control systems, digitally connected to the instrument PLC, making this drive the ideal system for static testing at fixed frequencies.

Dynamic Drives

Exclusively designed for usage in advanced static or dynamic rheometers, MonTech MDRs/RPAs feature a patented, wearless and stepless direct torque drive for the most demanding test sequences. Each motor is mounted directly under the lower die. Mounting the motor system underneath the lower die minimizes moving mass, and eliminates clutches, drive shafts, couplings and subsequent start delays.

Similar to the technology found in satellite motors, ceramic and magnetic bearings form the foundation of the drive’s high durability, stiffness and reliability, guaranteeing superior precision for the smallest strains or the highest frequencies.

Directly inline to the main drive system, a specially designed angular displacement sensor is mounted, with an accuracy of 0.000001° and response time of less than 20 nanoseconds.

These drive specifications make MonTech moving die rheometers the world-leading instrument series for reliable static and dynamic measurements.