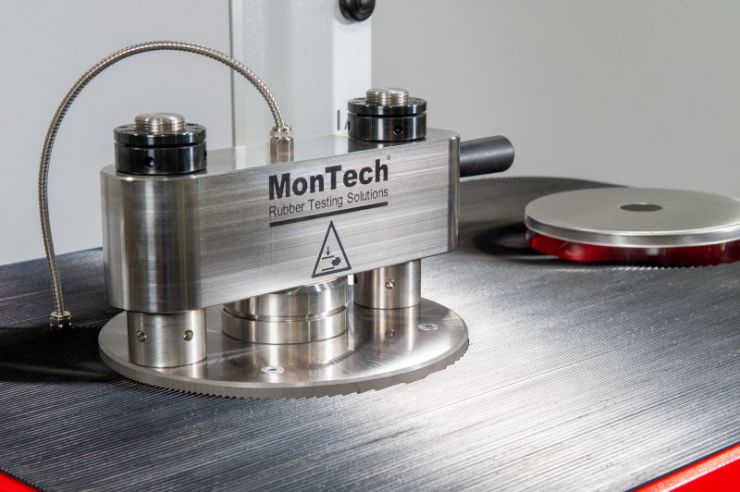

RD 3000

Uncured Rubber Density Tester

Precision Density Testing for Non-Vulcanized Compounds and Rubber Masterbatches

Uncured compression density is the fastest method for rubber mixers to reproducibly determine density of their final mix or masterbatch materials. Taking only seconds, the RD 3000 enables laboratory users to release materials for processing faster than ever. Due to the extremely rugged instrument design and easy sample preparation, the unit is available for placement in production laboratories or mixing environments. Connect to MES, Batch Release, Mixing, LIMS, and any production software.

RD 3000 Features

- 7” Color Control Screen

- Heavy-Duty Steel Crosshead

- Expanded Sample Volume and Density Ranges

- Integrated Scale and Wind Shield

- Digital Pressure and Piston Stroke Transducers

- MonDevice Software for ultimate connectivity

- USB, RS232, Ethernet RJ 45, Connections

Technical Specifications

Density | Range: 0.8 - 2.6 g/cm3 |

Sample Volume | Required: 40 - 120 cm3 |

Integrated Scale | Sample weight range: 0 - 420 g |

Compression Cylinder | Diameter: 60mm |

Pneumatics | Supply: 5.5 - 10 bar |

Data Interface | Ethernet Network (10/100 MBit), Serial RS232 (optional) |

Dimensions (H x W x D) | 43 in x 21 in x 29 in (1085 mm x 525 mm x 720 mm) |

Weight | approx. 190 kg net |

Electrical | 90-250 V, 1 Amp, 47-63 Hz, Single phase |

Environmental Conditions | Storage: Temperature - 25°C - + 55°C relative humidity 5 - 95 % |

Instrument Options | - Barcode scanner for compound and batch identification |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified