FT 3000

Rubber Flex Fatigue & DeMattia Crack Growth Tester

Discover fatigue and DeMattia flex crack growth properties with the highest precision rubber fatigue tester.

The Flex Fatigue and DeMattia Crack Growth tests stand as two of the most fundamental standards for understanding a rubber compound’s durability. With easily interchangeable fixtures, the FT 3000 accomplishes both tests with ease. This gives laboratories a dynamic and versatile instrument to test the life-cycle properties of elastomeric materials. Up to 16 samples can be simultaneously ran for either test method, with additional modules to enable access to more applications than ever. Select your test method, load the samples, choose the cycle count, and proceed.

FT 3000 Features

- Flex Fatigue and DeMattia Crack Growth methods included

- Advanced linear motor design with digital control and inline position measurement

- MonFT software included

- Programmable digital control panel

- Stainless steel grips hold up to 16 samples

- Grip sensors for precise detection of sample failure

- Definable frequencies, grip distances, and dynamic stroke

- Adjustable cycle settings with automatic stop

- Thermally regulated environmental chamber

Automated DeMattia Crack Growth Detection:

DeMattia Crack Growth testing can be a tedious process. In conjunction with MonFT software, test specimens can now be automatically inspected by our motorized CCD camera. After the defined cycle counts, the programmed camera records the propagation of crack growth for each sample. These measurements are then translated by MonFT software where a live plot of crack expansion can be seen and reported.

Customizable Waveforms and Test Sequencing

For high-end R&D laboratories, more customization enables greater access to newer or future applications. Pushing your tests to become closer to application requires customizable waveforms and dynamic test sequences.

Arbitrary Waveform Programming

Customizable waveforms allow users to assess fatigue properties with loading conditions closer to the application environment. Some loads are not pure sine waves. Dynamic loads can be translated to waveforms as pulses, squares, saw-toothed, triangles, or modulated sine waves.

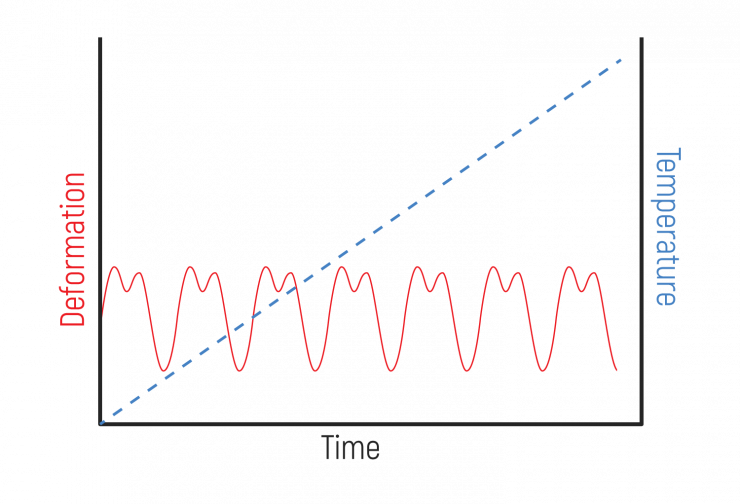

Arbitrary Test Sequence Programming

With this option, step-by-step test sequences can be programmed to exactly replicate an application or zero in on points where a part deteriorates. Customable variables include temperature, amplitude, frequency, time, cycles or waveform shapes.

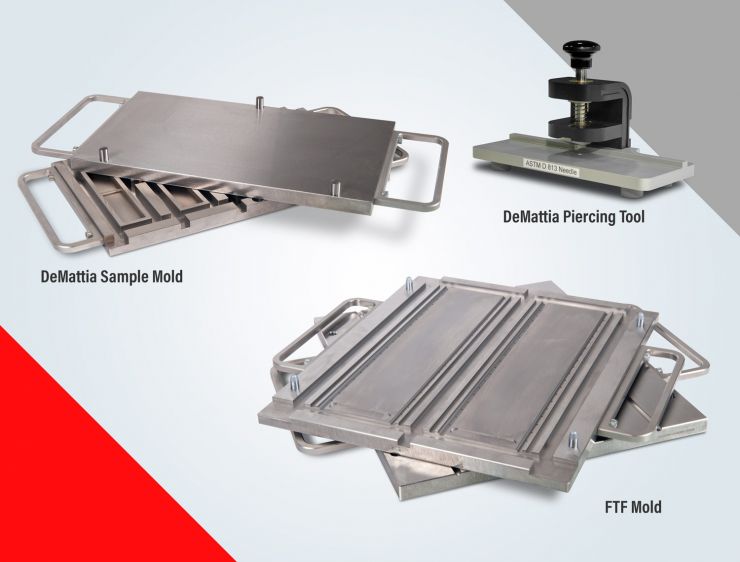

Sample Preparation for Flex Fatigue & DeMattia Crack Growth

The key to both test methods is proper sample preparation. Improper sample preparation is the leading contributor to poor test results. When purchasing the FT 3000, we can supply everything you need to get started. This includes:

- ASTM D430-B Mold

- ASTM D813 Mold

- Pneumatic Die Cutters

- DeMattia piercing tools

- Clicker-Press cutters

- Aging Ovens

- And more!

Technical Specifications

Standards | ISO 132 | ISO 6943 |

Speed Adjustment | Direct Linear Drive from 0.05 to 5 Hz (higher frequencies possible at reduced stroke) |

Dynamic Stroke | 0 to 60 mm (up to 150mm with reduced frequency) |

Static Grip Distance | 0 to 160 mm |

Maximum force in traction | 600 N (at 1 Hz oscillation frequency) |

Sample Holder | 16 samples can be tested at the same time |

Thermal Chamber Temperature | -40°C to 180°C with +/-1°C accuracy |

Dimensions (H x W x D) | 74.02 in x 47.24 in x 35.43 in (1880 mm x 1200 mm x 900 mm) |

Weight | approx. 870 kg net |

Electrical | 400 V, 50Hz, 16 Amps, Triple phase (480V / 60Hz version available) |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified