The mixing process is the most critical stage during the manufacturing of rubber compounds. While efficiency and short cycle times are keys to being competitive in the market, increasing quality requirements challenge rubber compounders.

A direct test to assess the mix quality of a rubber compound - including the distribution and disagglomeration - is a dispersion test to rapidly obtain quantitative results of the agglomerate and particle distribution, providing excellent correlation to mechanical properties such as abrasion resistance, crack growth, hardness, etc.

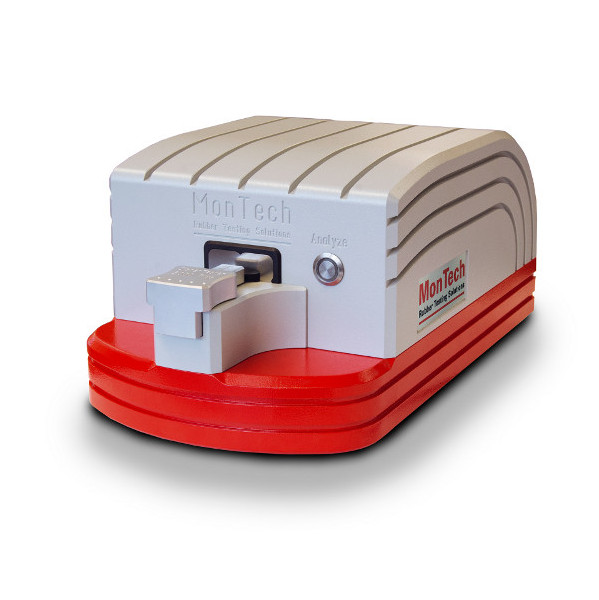

In quality control laboratories and directly in the mixing room, dispersion measurement is performed by a precision optical method. The new DisperTester 3000 Plus improves currently used methods by utilizing the latest computer based image processing technology and provides accurate, reproducible and quantitative test results. Easy sample preparation and quick automated test sequences allow test times of less than a minute - without the need for specialized operators.

The new DisperTester 3000 Plus from MonTech is built on the proven technology of the DisperTester product series that has been sold over the last 10 years with over 1000 units installed globally. With this new generation of Dispersion testers, MonTech is greatly expanding the possibilities of Dispersion testing as well as adding new, unprecedented features allowing faster and more accurate measurement of filler dispersion in the macro- and also micro dispersion range.

The new instrument offers complete digital technology featuring the most advanced digital USB 3.0 camera linked to a state-of-the-art MonDispersion software system for accurate image analysis in surface scanning as well as deep field scanning modes.

Automatic focus and integrated panning allows multiple readings from a single sample placement. Fully automatic sample handling systems for up to 50 or 100 specimens are optionally available.

Key Features:

- 10 Megapixel camera with telecentric optical system

- Variable contrast, brightness and exposure

- Multi-angle and direction LED illumination

- Multiple readings from one sample placement

- Agglomerates from 1 to 250 microns can be analyzed

- Automatic and manual scanning capabilities

- Meets ISO 11345 and ASTM D7723

- Auto-calibration

More information: DisperTester 3000 Plus